Vital Overview to Strapping Machine Repair: Guaranteeing Optimal Performance and Long Life

Strapping machines play an important function in product packaging and logistics. They can encounter different concerns that impede their efficiency. Recognizing these common issues and their hidden causes is vital for effective repair service and maintenance. Proper diagnostics and routine upkeep can prolong a machine's lifespan substantially. Many drivers neglect crucial maintenance actions. What are one of the most effective methods for ensuring these machines run at peak performance? The answers may amaze you.

Common Strapping Machine Issues and Their Causes

Although strapping machines are crucial for effective product packaging procedures, they can encounter various problems that interrupt process. Usual troubles consist of misfeeds, where the band does not feed correctly with the maker, frequently triggered by incorrect placement or used components. Another regular concern is strap breakage, which can result from using the wrong sort of band or too much stress throughout the strapping procedure. Furthermore, irregular seal toughness may happen as a result of inadequate warmth or pressure settings, leading to defective or weak seals. Dust and debris accumulation can likewise cause mechanical failures, impeding the machine's efficiency. Operators may additionally experience electrical breakdowns, such as faulty sensors or control failings, which can halt manufacturing. Recognizing these issues and their underlying reasons is crucial for keeping optimal performance and ensuring the durability of strapping machines in packaging procedures.

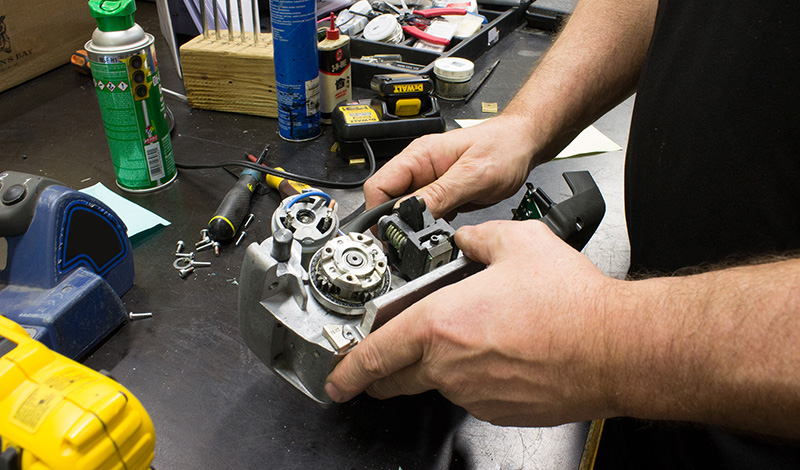

Vital Devices for Strapping Machine Repair

Resolving the usual problems that strapping machines experience requires the right devices to assure efficient repair work and maintenance. Essential devices include pliers, wrenches, and screwdrivers, which are vital for taking apart and reassembling elements. A multimeter is very important for diagnosing electric troubles, allowing technicians to determine faulty connections or parts. In addition, a torque wrench guarantees that bolts are tightened up to the manufacturer's specs, protecting against future break downs. Lubes and cleansing supplies are needed for normal upkeep, ensuring smooth procedure and long life of the machine. Replacement parts, such as belts, electric motors, and sensing units, need to also be on hand to promote fast repairs. Lastly, a comprehensive repair work handbook supplies invaluable guidance, helping service technicians navigate the complexities of strapping maker fixing efficiently. Employing these tools successfully can substantially boost the efficiency and life-span of strapping machines, lessening downtime and functional interruptions.

Step-by-Step Troubleshooting Guide

How can professionals successfully identify and solve problems with strapping machines? A methodical approach is vital. They should determine the signs, such as inconsistent strapping or equipment jams. Next off, specialists need to examine the user guidebook for certain error codes or fixing steps associated with the observed problems.

When signs and symptoms are kept in mind, they must examine the device's components, consisting of the tensioner, sealing head, and feed system for wear or damage. It is very important to inspect for proper placement and any kind of obstructions. After visual examinations, service technicians ought to check the electrical connections and sensing units to ensure they are functioning appropriately.

If problems continue, executing a functional examination after each adjustment will assist separate the issue. Documenting each step taken is very important for future referral. Following this organized troubleshooting overview allows technicians to efficiently determine the problem and apply effective repair work, therefore boosting machine dependability and efficiency.

Preventative Upkeep Tips for Durability

Implementing a robust preventative maintenance plan is crucial for guaranteeing the durability of strapping machines. Normal examinations need to be carried out to recognize any type of indications of wear or damages, concentrating on vital components such as belts, sensors, and rollers. strapping machine repair. Cleaning the machine regularly aids protect against particles build-up, which can click here result in operational issues. Lubrication of moving components is vital; utilizing the producer's recommended lubricants assurances smooth procedure and lowers rubbing

Additionally, operators ought to keep track of the maker's efficiency metrics, keeping in mind any kind of irregularities that may suggest possible problems. Keeping a detailed maintenance log aids in tracking solution history and scheduling prompt treatments. Training staff on correct usage and handling can significantly decrease the threat of operator-induced damage. Finally, changing worn components proactively, as opposed to reactively, can reduce downtime and extend the maker's lifespan. Complying with these preventative maintenance tips will add to excellent efficiency and sturdiness of strapping machines.

When to Look For Expert Help

Furthermore, when components show signs of wear or damages, professional assessment ends up being important to ensure safety and security and capability. Looking for assistance from qualified professionals is advisable if internal maintenance team do not have the know-how or devices to diagnose complex problems. Routine appointments with professionals can also help in determining possible issues before they intensify. Inevitably, prompt treatment by specialists not just lengthens the lifespan of the equipment but also safeguards productivity, ensuring that operations stay reliable and smooth.

Frequently Asked Inquiries

Just how Commonly Should I Replace the Strapping Machine's Parts?

Strapping machine components must be replaced every 1-3 years, depending on use and wear (strapping machine repair). Routine examinations and maintenance can help identify components needing replacement earlier, making sure perfect capability and reducing the danger of unanticipated failures

Can I Make Use Of Various Strapping Materials With My Machine?

Different strapping products can often be used with a device, supplied they satisfy specific dimension and stress requirements. Compatibility should be validated to guarantee peak performance and avoid prospective damage or breakdown.

What Are the Indications of an Overheating Strapping Machine?

Indicators of an overheating strapping equipment include uncommon noises, regular shutdowns, extreme heat originating from components, smoke, and inconsistent strapping top quality. Timely recognition of these signs is necessary for preventing damage and ensuring efficient procedure.

Exactly How Can I Enhance Strapping Speed Without Sacrificing Top Quality?

To enhance strapping rate without sacrificing high quality, one can maximize maker settings, use top notch products, maintain tools regularly, and train drivers in effective strategies, making sure a balance between speed and effective strapping performance.

Are There Particular Brand Names Understood for Better Resilience?

Specific brands, such as Signode and Mosca, are renowned for their sturdiness in strapping machines. Their durable building and construction and high-grade materials commonly lead to prolonged life expectancies and reputable efficiency in requiring commercial environments.

How can specialists effectively diagnose and settle concerns with strapping machines? They ought to determine the symptoms, such as inconsistent strapping or device jams. Executing a robust preventative maintenance plan is crucial for assuring the durability of strapping machines. Different strapping products can usually be made use of with an equipment, offered they meet certain dimension and tension requirements. Signs of an overheating strapping machine include unusual sounds, regular shutdowns, extreme warmth emanating from parts, smoke, and irregular strapping high quality.